Do you have a certain amount of cash you would like to spend on new tools?

Buying used woodworking machinery is a great way to save. Here’s why and how you should go about it so that you don’t fall into any traps of buying the wrong thing for your needs or not getting what you want out of them.

What are second hand woodworking tools?

Measuring

There are many different measuring devices for sale available for woodworkers, but the essential ones are listed below:

- Measuring tape: Measuring tapes are typically 25 feet long. Tape measures have a hook on the end to measure around corners or over obstacles.

- Yardsticks: Yardsticks are another essential measuring instrument for woodworkers. They are usually 3 to 4 feet long and have markings every inch or so. Yardsticks can be used to measure long pieces of lumber or other materials.

- Ruler: Rulers come in various lengths, but the most common size is 12 inches. Rulers with inch marks help measure smaller pieces of wood and other materials.

- Square: A square has two arms that meet at 90 degrees (a right angle). Squares are used to check if a piece of lumber is cut at a 90 degree angle (or to find the angle a piece of lumber is cut at). Many types of squares are available, but the most common is the steel square.

My opinion: Personally, I wouldn’t bother buying them secondhand. Tape measures are notoriously inaccurate, even when new. The hook could be bent in either direction affecting accuracy. Rulers also suffer lots of abuse, whether intentional or not. Running a knife along a rule will wear the edge through time. Squares suffer the same as rulers and other abuse.

Sawing

There are many saws on the market, each designed for a specific purpose. The most common saw in carpentry is the panel saw. Other types are mitre saw, circular saws, jigsaws, bandsaws, and scrollsaws.

Drilling

Eggbeaters, braces, cordless, and modern power drills are all examples of drills. They are used to create holes in lumber and come in various sizes and shapes.

Where to find them: You can find drilling gear at most hardware stores or internet retailers that sell construction supplies.

Shaping

There are many shaping devices, each with advantages and disadvantages.

The most common include saws, chisels, planes, routers, and sanders. Each device has its specific purpose and can be used to create various forms.

Saws: Saws are one of the most fundamental prerequisites for shaping. They can make straight cuts, curves, or intricate designs. Sawblades come in a variety of sizes and can be made from different materials, such as steel or high-carbon steel.

Chisels: Bench chisels are essential to creating straight or curved lines. Chisels come in various sizes and shapes depending on their intended use. There are carving chisels with multiple forms and sweeps to carve detailed designs.

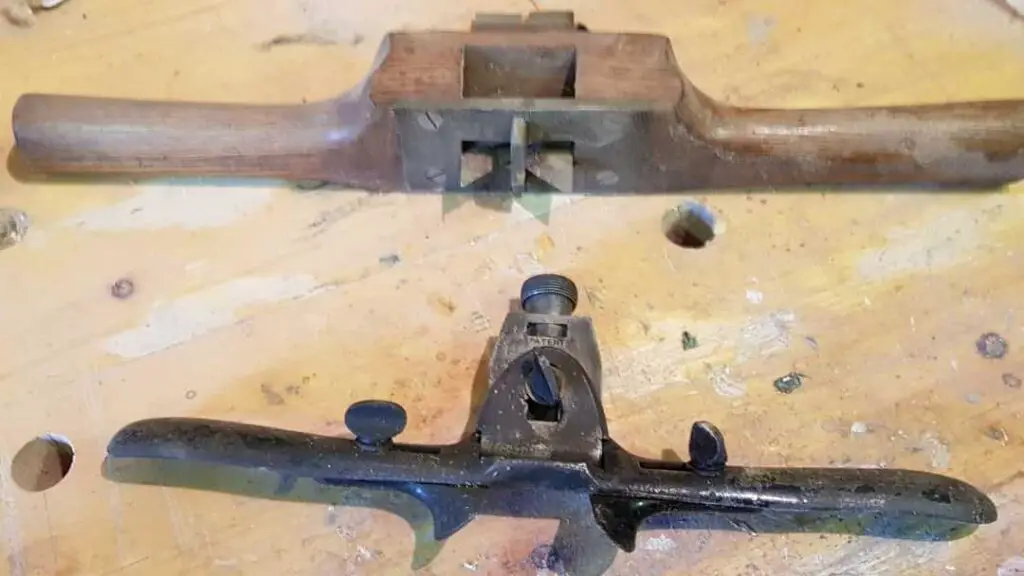

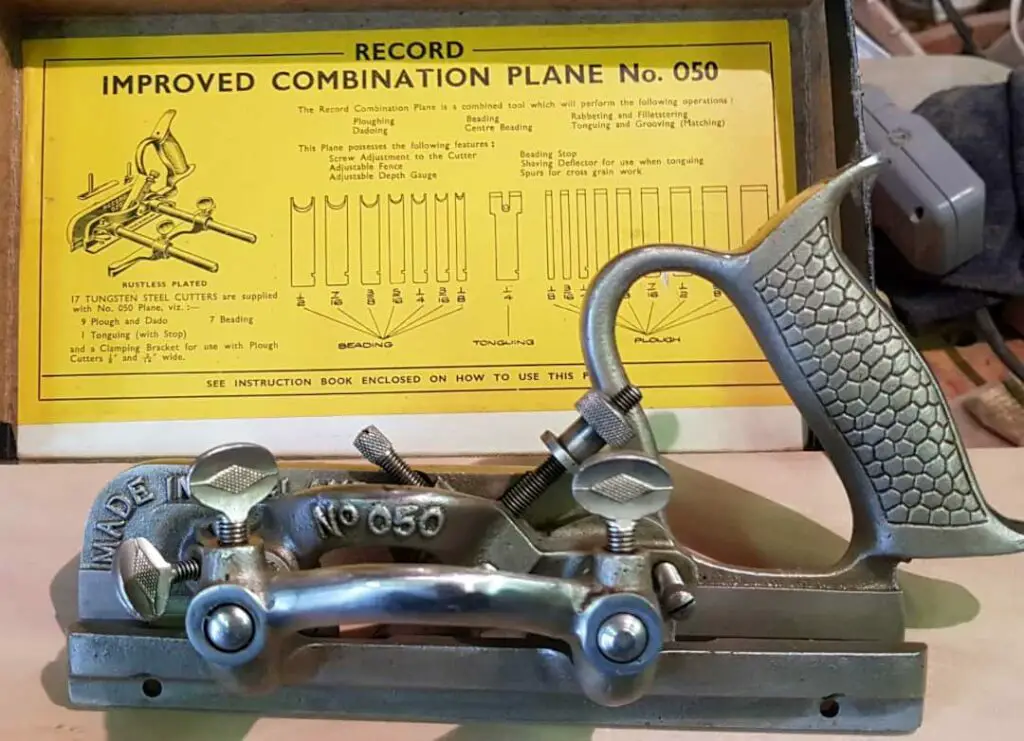

Planes: Record / Stanley planes are adaptable to smooth rough surfaces, create rabbets, and trim stock.

Routers: Versatile for creating rabbets, dadoes (a type of cut), or shaping edges. Woodworking routers come in various sizes and can use different router bits to form many shapes.

Sanders: Used for smoothing rough surfaces or for shaping. It is possible to generate varied textures when fitted with various sandpapers.

What are the benefits of buying quality used woodworking machinery?

- When you buy used, it is often significantly cheaper than new.

- Older machinery was built to last with cast iron.

- Machine weight can be a big advantage with stability and rigidity.

Disadvantages:

- Used workshop machinery might not be as reliable as new units. They can break down more often and require more repairs.

- Older machines might not have all the features of newer models. It can be advantageous because it forces you to become more creative in your workarounds.

- Weight of the machine can be a big disadvantage if you have to move things for space in a small shop.

Shaper machines

Band saw

The bandsaw can easily cut through materials of varying widths to create uniform portions of lumber. Bandsaws are less durable than circular saws because they use a tensioned band. However, as consumables, replacement bands are affordable.

Not much to go wrong just bearings and motors. It could be missing the fence, but easy enough to make a replacement. Look for cutting depth and throat size.

Tablesaws

No machine in a woodshop sees as much action as the table saw. The fence, arbour, and flat table are all designed to facilitate various machining processes.

You can find a cast iron monster for not much money. Schools and businesses favoured Startrite and Wadkin saws for a good reason.

Planner/jointer

Jointers: A jointer consists of an infeed table, a rotating head with blades, and an outfeed table. Jointers flatten a board’s bottom so it will pass through a planer and tablesaw.

Planers: A planer thicknesser flattens boards to a specified thickness. You may use a planer for workpiece processing rough timber and multi-layer panels. They vary from tiny, portable units to huge, industrial ones.

There are also combination machines that do both. Mine was already obsolete in the year 2000; it has a detachable motor to go on a spindle moulder. Motors were expensive in the 80s, so they made them switchable between units.

Drill press

The simple hand drill has developed into a powerful drill press station. Using them, any borehole design can be bored with consistent results. Boring devices are in high demand in the furniture industry because they help in working with sheet goods.

Doweling machines

The huge range of drilling equipment also contains dowelling machines. Boreholes are introduced to wooden products for dowels, and threaded pins, to be inserted. This allows flatpack furniture, where the purchaser must assemble the final product. Drilling and dowelling make modern flatpack furniture possible.

Belt and disc sander

Available as a standalone or a combination unit. A belt and disc sander is a multi-use tool for sanding wood, shaping metal, and polishing. They are powered by an electric motor and have two sanding surfaces. The wide belt is typically used for coarse sanding, while the disc is for finer sanding. They are considered to be one of the most versatile available.

Sanders remove material from hard surfaces using an abrasive disc or belt.

Bobbin sander

A Bobbin Sander is a machine used for sanding or shaping. It has several round drums to choose the nearest option. This sander is often used in furniture making and other wooden objects.

The round drums are filled with multi-grit sanding papers for a polished finish. A motor turns the sandpaper drum, and the shaft oscillates with it. Leaving a smooth finish on your workpiece.

Spindle moulder

Similar to a jointer and planers, spindle moulders create profiles and forms into stock. A shaper has a rotating head mounted on a vertical shaft and a variety of cutters of varying sizes to achieve its desired results.

A good router table does a similar job on a smaller scale. Very versatile; use your imagination for the possibilities.

Woodturning lathe

A woodturning lathe can shape wood and other materials into the desired final product. It has a headstock and tailstock, allowing the user to rotate pieces clamped between centres.

Lathes provide carpentry and furniture making, endless creative possibilities.

What are the risks of buying used woodworking machines?

- Theft.

- Vandalism.

- Damage from weather or other natural disasters.

- Loss of money if not as described.

- It’s possible it may be outdated and not as effective as a newer model.

Benefits:

- Can be cheaper than purchasing new.

- If you know what you’re doing, you can get heavy-duty machines for a fraction of the price.

How to test:

Before getting any wood shop machinery, you must inspect it thoroughly. Make sure all the components are there and in good health. Test the machine to see if it works properly. If possible, take it for a test run before making your purchase.

How do you choose the right used equipment items for you?

Consider your goals.

Do you want to be a woodworker who makes things for others, or do you want to make things for yourself?

What sort of craftwork do you want to do:

Do you want to work with small or large pieces of wood?

How much space do you have:

Do you have a garage or shed to use as a workshop? How big is it?

How much money do you want to spend:

Are you looking for cheap standard woodwork machines, or are you willing to spend more money on better quality?

Consider the type of wood you will be working with

There are many different types of wood, each with its unique characteristics. What you use will affect the sort of equipment you require.

Hardwoods: Hardwoods are denser and more challenging to deal with than softwoods. They are ideal for furniture and cabinetry but can be more challenging for beginners. Popular hardwoods are oak, maple, cherry, and mahogany.

Softwoods: Softwoods are lighter with easier workability than hardwoods. They are often used for framing and other construction projects. For popular softwoods, think pine, cedar, and fir.

How to choose the right type of used woodworking equipment:

The type of equipment you want depends on the kind of project you’re working on. If you’re just starting, it’s a good idea to get the basics that will allow you to complete simple projects. As you become more experienced, you can add more specialized items to your collection.

Consider the size of the projects you will be working on

Depending on the nature of the job, different requirements will be needed from task to task. If you plan on working on large jobs, you will need larger tooling and a more spacious workplace. If you only plan on working on smaller projects, you can get by with smaller stuff and a more compact workspace.

Work area:

Your shed/garage should be large enough for all your equipment, project materials, and finished products. It should also be well-lit and ventilated to keep your workspace comfortable and safe.

Storage space:

You will need enough storage space for your apparatus, supplies, and finished items. If you don’t have designated storage, keep your workstation clean and organised, so everything has a home.

Choose secondhand machines that are in good condition.

Reliability:

When choosing items, good condition is essential. Look for signs of wear or damage, such as cracks in the body. Check for the availability of replacement blades; you don’t want anything obscure. Avoid anything that looks dodgy; it might be unsafe to use.

Safety:

Safety is always a priority when working with any machinery. Check used equipment for intact and operating safety features.

How much space do you have available?

You need to have a designated workspace. This can be as simple as a cleared area in your garage or basement. If you have the room, a dedicated shed is ideal. The size of your workbench determines the projects you plan to build and the available space.

Storage: Adequate storage is essential for any workshop. You’ll need space for lumber, supplies and finished products. Equipment takes up quite a lot of space, so plan accordingly.

Shop Layout: Workshop layout depends on the size and form of your accessible space. After deciding where to put your workbench and storage, design the remaining space. Think about the workflow as timber comes in the door and the working sequence.

Do your research

You need to know what you want to do with your machinery. What are your goals? What are your skills? What do you need to complete your project?

Compare prices: Once you know what you require, compare the prices of different brands and models. Don’t just go for the cheapest option, but also consider quality.

Read reviews: Finally, read reviews of the products you’re considering. See what other people have said about them; forums and Facebook groups are helpful. This can be a great way to get more information about a product and help you make a final decision.

How do you care for old equipment?

First, remove any dirt, sawdust or other debris to clean them. Soak overnight in vinegar if possible, then a soft cloth dampened with water to remove it. Next, apply a light coat of oil to help protect them from rust. Finally, wipe down with a clean cloth to remove any excess oil.

Storage:

It is important to store your equipment in a dry place. This will help prevent rust and other damage. If possible, keep them in a climate-controlled environment. Consider using covers or bags to protect things from dust and debris.

Preventing rust:

One of the best ways to prevent rust is to keep everything clean and well-oiled. Additionally, you can try using a product like WD-40 or camellia oil to help protect from rust.

What are common problems with secondhand woodworking machinery for sale?

Used equipment for sale may not be as accurate:

Many factors can cause machines to be inaccurate. The most common factor is wear and tear. Over time, the moving components will start to wear down, which can cause them to become less accurate. Another factor that can cause inaccuracy is damage. If dropped or struck, it can damage the internals affecting accuracy.

How to test for accuracy:

The best way to test for accuracy is to use a measuring tape or ruler. Take an accurate measurement on the blade side and see if it lines up with the other side. If it doesn’t line up perfectly, then the tool is inaccurate.

What to do if it is inaccurate:

If you find your tooling inaccurate, there are a few things you can do to try and fix it. The first thing you can do is calibrate the instrument. This won’t always work, but it’s worth a try. You will have to replace some internal elements if calibration doesn’t work. This will likely require taking it apart and then putting it back together again.

Machinery and tools for woodworking may not be as sharp as new

Used machinery may not be as sharp as new, making your work less precise and taking longer. It’s not a problem, though, as blades are considered consumables.

How to fix it: You should learn to sharpen them yourself with a stone as part of your daily routine. A professional sharpening service can sharpen your machinery blades.

Used machines may not have all the new features.

When looking for quality woodcutting machinery, it is vital to inspect the item for any damage. Look for cracks, chips, or missing pieces. Also, check to see if it is complete with all the necessary accessories.

How to test:

If possible, test before you buy it. If you buy a power tool, plug it in and turn it on. If it is a hand tool, try using it on a piece of scrap wood.

What to avoid:

Avoid machinery that is in poor condition or has missing parts. Also, be cautious of those that have been modified or repaired by someone who is not a professional.

How do you troubleshoot new and used industrial machinery?

When it comes to anything used, safety is the top priority. Before using any device, always inspect it for damage or wear that could cause injury. If you are unsure about a particular safety concern, consult a professional before using it.

Functionality:

It is vital to ensure that your potential purchase is still in excellent condition. Inspect it for any signs of wear or damage that could affect its performance. If possible, test before purchasing to ensure it meets your needs.

Reliability:

When purchasing anything, you want to be sure that it is reliable and will last for years. Check the brand and model’s performance and durability before purchase.

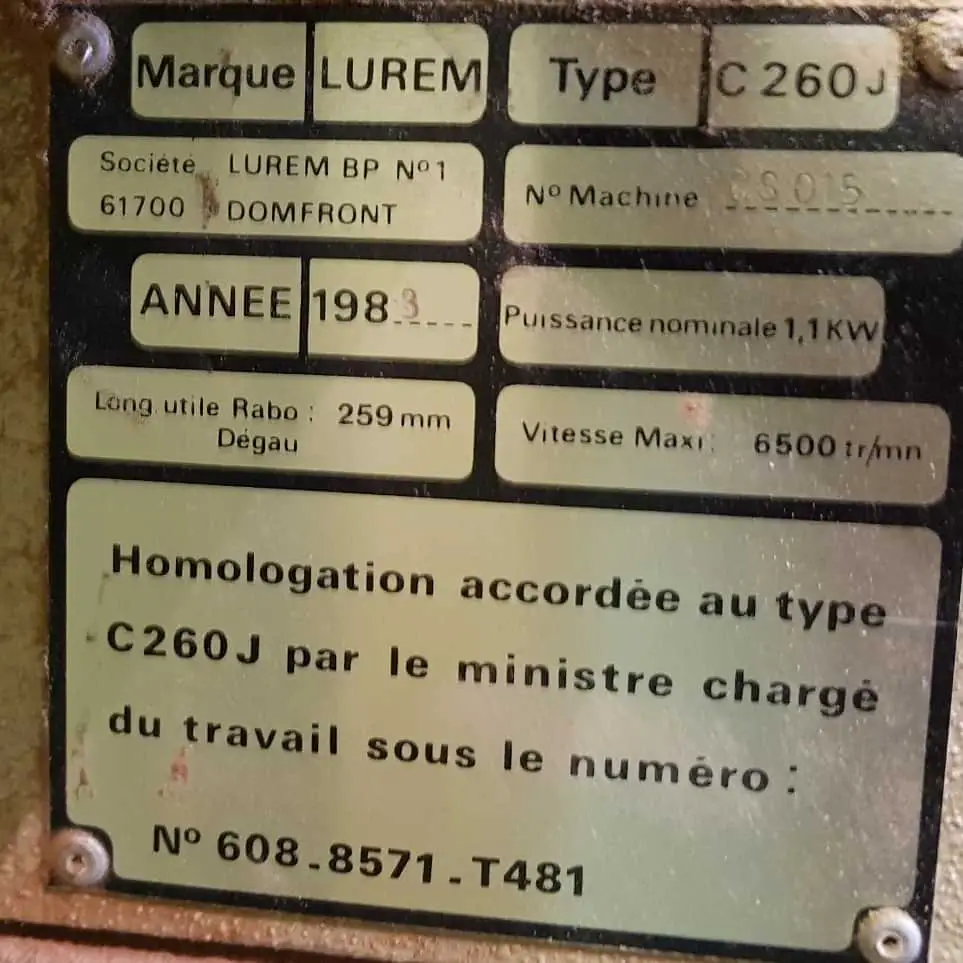

How do you find replacement parts for a particular used machine type?

Look for replacements online.

Online is the best place to start looking for a replacement. There are a lot of websites that sell replacement bits for a wide range of tools.

How to find the right part:

When looking for a replacement, finding the correct part is vital. To do this, you will have to know the model number. Once you have this info, search on an appropriate website.

What to do if you can’t find a replacement part:

If you cannot find a replacement, contact the manufacturer directly. They might be able to provide you with the information that you need to find a suitable replacement part.

Check with the manufacturer

- Check for a name or logo.

- Check any documentation that came with the tool.

- Do a search for the make and edition.

- What to do if the manufacturer is no longer in business:

- Try contacting a company that specializes in selling vintage tools.

- Look on websites like eBay or Craigslist.

Ask other woodworkers

There are a few ways to find woodworkers who can assist you find secondhand components. Ask around at your local craft store or club. Another is to search woodwork forums or social media groups. Finally, you could try posting a question on a website like Quora or Reddit.

How to ask for help:

When asking others for help, be specific about what you’re looking for. Mention the make and model, and if possible, include a photo. It’s also helpful to let people know where you’re located, as this can narrow the search. Finally, be sure to thank anyone who takes the time to respond!

Look for used parts

There are a few places you can look for used tool parts. One option is to check classifieds or auction websites. Another option is to visit local garage sales or flea markets.

What to look for:

When viewing a used part, always scrutinize it carefully. Make sure the spare part is not damaged and is compatible with your own. It is a good idea to compare prices before making a purchase.

How to install:

Once you have found the perfect part, it is crucial to install it correctly. Make sure to read the instruction manuals and follow them carefully. Ask a friend or family member for help if you are unsure about something.

What are some safety tips for using old machines?

- Check for cracks, breaks or other damage before using.

- Inspect cords and plugs for damage before using anything electrical.

- Be sure blades are sharp and properly secured before using saws.

- Make sure all moving gear is correctly lubricated before using.

- Check that all safety devices are properly functioning before using anything electrical-powered.

Maintenance:

- If it’s a complex machine you have never used before, check the web for an instruction manual.

- Keep things clean and well-oiled to prevent rust and corrosion.

Where to buy used woodworking tools?

Online

eBay is the largest place to start if you’re searching for secondhand. You can find a variety of vintage and antique stuff on eBay, from chisels to planes and everything else. Prices will vary depending on the age and condition, but you can often find great deals.

Amazon:

Amazon is another excellent option. On Amazon, you can discover new and used options from brands like Dewalt or Makita. Prices will again vary, but you can often find good deals on both.

Etsy:

Etsy is a great option if you’re looking for vintage or handmade. You can find a variety of new and used from small business shops worldwide. Costs will vary, but you can often source specialist items.

Yard sales

Yard sales are a great place to buy bargains. Look for bench planes, chisels, hammers, saws, and screwdrivers. These will be useful for a variety of projects.

How to negotiate:

You will need to be prepared to negotiate with the sellers. Be sure to have a reasonable offer in mind before you start bargaining.

What to avoid:

You should avoid some things when buying at markets. First, avoid anything that is damaged or broken. Second, don’t purchase used unless you can maintain them.

Collectable and antique auctions

- An abundance of online and traditional auction houses have constant stock.

- Online marketplace websites are a great place to start your search.

- Estate sales, garage sales, and thrift stores can be good sources with time and effort.

How to bid:

- When bidding, know what you are looking for and what it is worth.

- Do some research ahead of time so you are aware of what to expect in terms of price.

- Start with a low bid and increase your submission as necessary.

- Be prepared to walk away if the price gets too high.

What to avoid:

- Bidding without doing any research first is a recipe for disaster.

- You could end up paying too much or getting something unsuitable for your needs.

Dictionary of tools used in the woodworking and allied trades, c. 1700-1970

This book is good if you want more information on vintage bench tools.

Finishing Up

There are pros and cons to buying used. Do your homework to make sure you are getting a good deal on a quality piece of equipment. With a little research, you can find used kit that will save you money and last for years.