When working with wood, a quality router table is one of the most important tools you can have in your shop. This allows you to add intricate details to your projects, enhancing their overall quality and impact. Choosing the perfect router table can be difficult with so many options on the market.

We have put together this ultimate buying guide to help you choose the best router table for the money.

What is a router table?

A router table is a woodworking tool that provides a stable platform for a handheld router. It allows for increased accuracy, more control and can use larger bits. The use of a router table allows amateur woodworkers to create joints and complex decorative mouldings on pieces of wood.

The table should have a standard dust spout, a strong top, and adequate space for work. Overall, the router table pros and cons make it a must-have tool for any woodshop.

The top 10 best router tables

1. Kreg PRS2100 Bench Top Router Table

One of the key features of the Kreg PRS2100 is its sturdy and solid base, which stays in place while you work. The table is made from heavy-duty steel and has a durable, wear-resistant MDF top measuring 16″ x 24″. Engineered with multiple mounting options to attach both fixed and plunge base models.

A breeze to set up, with useful features, such as an easy-to-use adjustable fence and a dust collection port. Durable and built to last, so you can expect to get many years of use out of it. When it comes to price, the PRS2100 offers competitive value.

Pros

- Well constructed.

- Easy to use.

- Comes with a variety of useful stuff.

- Large table surface for bigger projects.

- Compatible with a wide variety of routers.

Cons

- Assembly can be time-consuming.

- May require additional accessories for optimal use.

- Could weigh too much for users at 28.4 lbs.

- Price may be a bit steep for some.

- Dust collection could be better.

2. Bosch RA1181 Aluminum Benchtop Router Table

One of the standout features of the Bosch RA1181 benchtop router table is its ease of use. Clear directions make assembling simple. The table also comes with mounting hardware that makes it easy to attach a router to the table. The flat aluminum table is both enduring and lightweight.

In terms of accuracy, the Bosch RA1181 delivers exceptional results. The table’s components are designed to endure constant usage. The tall fence is adjustable, permitting accurate and consistent machining. The aluminum miter gauge slot is advertised as 3/4 inch. Supplied with a lead-in pin for freehand or curved work.

- Large workspace of 27 inches by 18 inches.

- Tough aluminium construction.

- Compatible with various router brands.

- Includes two adjustable featherboards for added security.

- Comes with a pre-drilled router mounting plate for easy setup.

- Poor build quality.

- Confusing directions for putting together.

- Mitre slot is not as marketed.

- Some problems with the top being warped.

3. Dremel 231 Portable Rotary Router Table

The Dremel router table can convert a Dremel rotary tool into a wood shaper. It’s lightweight and small, so it’s simple to carry and store.

The table has an adjustable fence for accurate routing, and easy manoeuvrability. DIYers may use the Dremel 231 with various Dremel tools. However, its smaller size may limit its capabilities for anything but model makers. To maximize its performance, it is recommended to use a higher RPM.

Prioritizing common sense when working is absolutely essential. You must ensure your wearing eye protection and secure it to a workbench using C-clamps or screws. Overall, the Dremel 231 is a great addition to any workshop with a need for small precision routing.

- Portable and lightweight design.

- Easy to rig up and use.

- Compatible with Dremel rotary tools.

- Adjustable router fence.

- Affordable price for a compact router table option.

- Compatibility with non-Dremel tools.

- Plastic construction may not be as durable.

- Small size may not accept broader pieces.

- Some people report difficulty with adjusting.

- More vibration than solid tables.

4. Kreg PRS5000 Precision Router Lift

The Kreg PRS5000 Router Lift replaces the router base plate, allowing micro-adjustments to bit heights down to 1/1000th of an inch. Without removing the router, the handle raises the cutter for easy bit changes.

The lift plate is 3/8 inches thick, 9 1/4 inches wide, and 11 3/4 inches long. It is compatible with twenty popular router brands, I own four hand-held routers, and none will fit. However, the PRS5000 lacks a table fence system and may not be compatible with certain Bosch router models.

Overall, this is an ideal choice for reliable router operations.

- Durable construction.

- Easy to adjust from above the table.

- Wide micro-adjustment range.

- Built-in locking mechanism for secure use.

- Slick and consistent operation.

- Expensive compared to other insert plates.

- Some users report difficulty with initial levelling setup.

- Compatibility with European plunge routers.

- Big depth changes take a while.

- Some individuals report issues with the lift mechanism.

5. JessEm Mast-R- II Router Lift

The JessEm Lift is a superior metric or imperial option for professional joinery firms. These were excellent products when I started over 20 years ago, but now with lots of imitators. It weighs in at a hefty 13.69 lb and is made from hard anodized aluminium 1/2 inch thick by 13.7 x 11.2 inches. This lift fits most fixed base routers with a reliable depth adjustment mechanism.

One of the most significant advantages of this router lift is its ease of use. Effortless changing and adjusting of the router bit height gauge for more convenience. The Mast-R-Lift has a scale for a precise height adjuster and locking mechanism to prevent the router motor from slipping. The precision gears ensure it maintains efficiency and can withstand heavy-duty work.

Beginners and casual hobbyists may not like its hefty price and complicated traits. Building a precision router table system from all JessEm items, stand, phenolic top, and fence will cost you between $1,700 – $2,200 USD.

- Has stood the test of time.

- Plate-leveling arrangment.

- The price is out of budget for most.

6. Grizzly Industrial G0528 – Sliding Router Table

The Grizzly Industrial G0528 router table is top-of-the-line for enthusiasts and professionals alike. Its large cast iron slab of 31″ x 10″ makes it suitable for a variety of woodworking tasks. The table is compatible with a variety of routers, ranging from 0.75 to 5 hp.

Other advanced features include a 31″ x 12 1/4″ sliding table and a paddle switch for easy on/off access. The steel stand and shelf add to its stability and durability. For upgrading, the G0528 is great, but the extruded aluminum fence could be improved.

- Industrial use.

- Cast iron top.

- Fence is not to Incra standards.

- Weight of the tilted top is a safety issue for some.

7. Woodrat WR 900

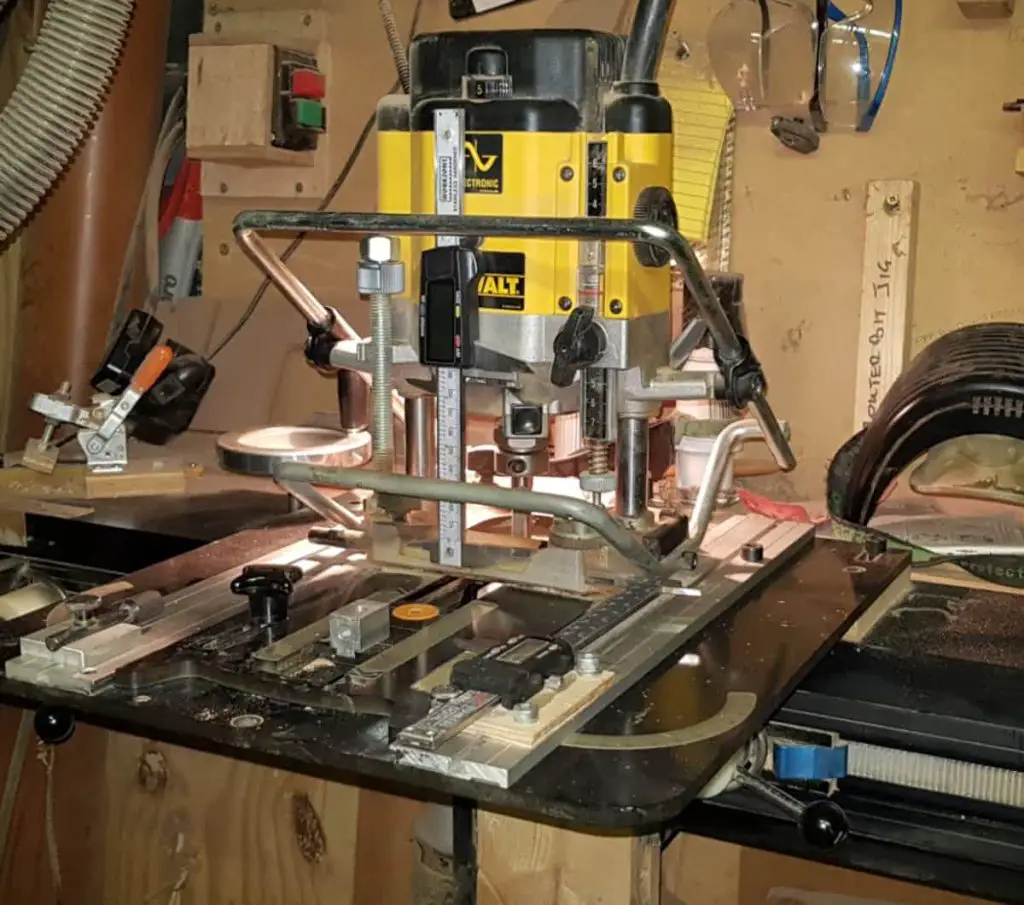

Well, the Woodrat WR 900 is an unusual one that I bet you never heard of; the one pictured is mine, so excuse the mess. Is it a router table or a jig? A bit of both, really; I would do some things like raising a panel on a regular table, but all other joints are made here. Best suited to small production shops or cabinet makers cutting every type of joint you can think of.

Dovetails that look as if hand-cut with no template? The limitation is the router cutter; you need Woodrat’s steel bits which are small. You can also use the mortice rail accessory for mortices in a door style.

Everything listed so far has not mentioned a power feed. While the setup doesn’t have one as such, it comes pretty close. You control the movement north and south with your right hand while the L/H cranks the carriage wheel. Climb cutting is dangerous, but here it’s taught stopping feathered edges and breakout.

For dust extraction, mine is hooked up to the 4″ port of the chip extractor, a 2″ straight bit on a tenon can make a lot of mess fast 😉. A special box needs building for this; it’s all in the detailed instructions and is also a storage box for its odds and ends.

One of the key benefits of the Woodrat WR900 is its versatility. Experienced woodworkers who need flexibility may use this with a variety of different routers. The price point may be prohibitive for some, so look for a secondhand machine, or it’s smaller brother.

If versatility is a priority for woodworkers, the Wood rat WR900 is an excellent choice. Despite the limitations, its benefits make it a router table package worth considering.

Pros

- Performs multiple functions.

- Flawless joinery creations.

Cons

- Expensive.

- Not many about so you will have to figure jigs out yourself.

- Not suitable for all tasks.

- Steep learning curve.

8. Skil RAS900 Router Table

The Skil RAS900 is one of the best budget Router Tables as an affordable solution for woodworking enthusiasts. Easy to carry and store this portable router table measures 27 x 17.75 x 9.25 inches and weighs only 32 pounds. An MDF substrate that is both durable and smooth, provides a stable working area for your projects.

One of the distinguishing characteristics of the Skil RAS900 is its multifunctional fence. The fence and starter pin can be easily adjusted to accommodate different routing operations. You can attach a shop vac to keep your workspace clean. The table has a quick-release router mount for installing and removing routers easily.

The RAS-900 has a variety of mounting options, with pre-drilled holes to secure it to a workbench. Folding legs on the benchtop table give stability on uneven surfaces.

An ample tool storage capacity and convenient cord wrap keep things organized.

- Compact construction.

- Easy to set up.

- Adaptable fence for edge jointing.

- Compatible with most router models.

- Difficult to accurately adjust the fence.

- May require additional modifications.

- Some users report problems with the mounting plate.

- May produce more vibration than larger tables.

- Dust collection system may not be effective.

9. Ryobi Universal Router Table

The Ryobi Router Table is a high-quality piece of equipment compatible with all major brands. Its laminated MDF work surface and sturdy plastic legs provide a stable work area. While the split fence and five throat plate sizes allow for precise cuts.

The table has a T-track for mitered cuts and a built-in vacuum port fitting a 1-1/4″ or 2-1/2″ pipe for sawdust control. While it may not be particularly portable at 29 lb, it’s excellent for any workshop with a 3-year warranty. The only potential drawbacks are a lack of storage and some difficulty with assembly. Overall, the Ryobi Universal Router Table is versatile for any enthusiast.

Pros

- Two-piece fence.

- Five throat plate sizes.

- Good value.

Cons

- Not very portable.

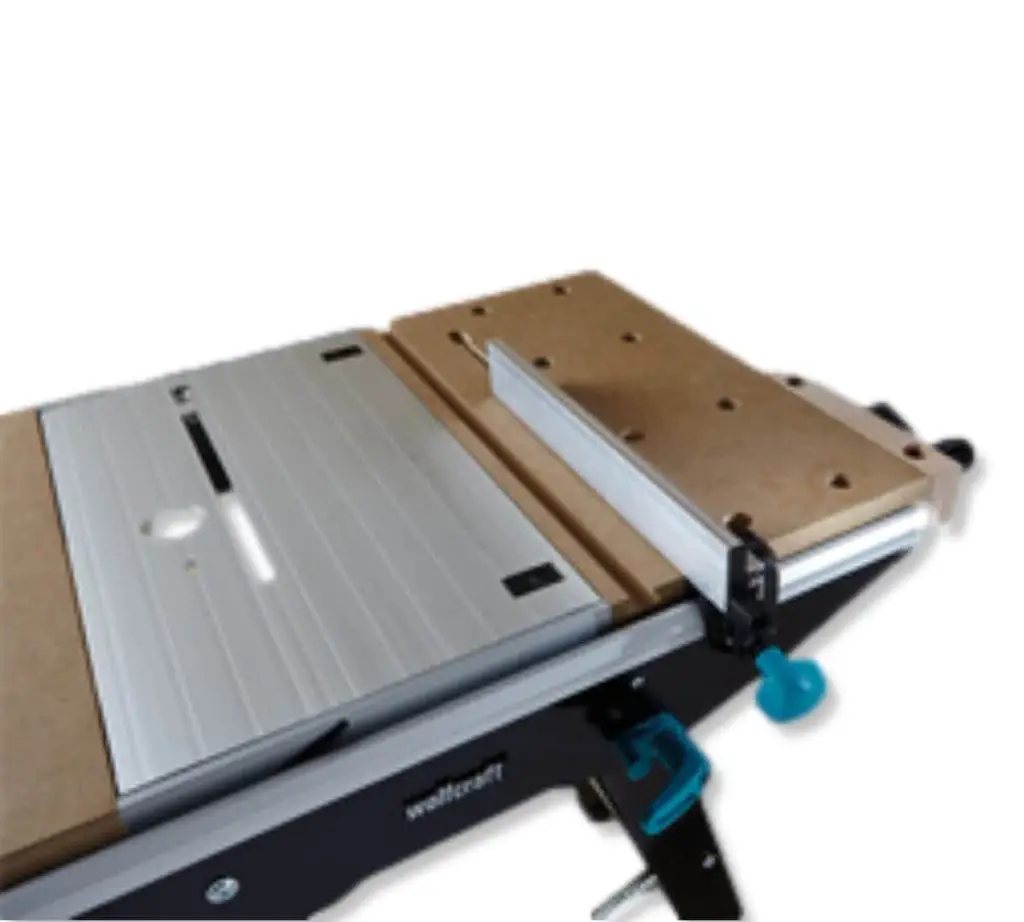

10. Wolfcraft Master cut 1500 Work and Machine Table

The Master Cut 1500 Work and Machine Table is made to accommodate a router, jigsaw or circular saw, ideal for a novice or DIY projects.

As a metal router table, it offers a large work surface of 700 x 1150 mm. It also features guide rail hardware for precise cuts and easy tweaks.

The Wolfcraft Master Cut’s compatibility with other models is notable. It comes with a universal router mount, so is great for those who want to upgrade their workspace. It has a built-in NVR button and dust port that helps keep your workspace clean and safe.

The portable table has a load capacity of up to 200 kg but can be easily folded and stored when not in use. It features sturdy legs that provide a rigid base for you to clamp your workpiece in the beech vice.

The Wolfcraft is a substantial router table with several capabilities to boost productivity. It’s a top-notch selection, for sure.

Pros

- 10 years guarantee.

- Accepts other power tools.

- Can handle enormous loads.

- Ideal for those with little shop space.

Cons

- Challenging to assemble unless you read the documentation 😉

- Not for cordless tools (the NVR button won’t work).

- Not everyone’s cup of tea.

Watch Videos about Best Router Tables in 2023

If you’re thinking about buying a router table, it’s important to do your research before making a purchase. Watching videos is one of the best ways to learn about the best router tables of 2023. Videos can show the downsides and how they perform in real life. By watching, you can better understand what to look for and make an informed decision.

What to consider when choosing a router table

Consider your specific requirements when purchasing a router table for your woodworking projects. Think about the table’s size, material, adjustability, and compatibility with your router. A sturdy base is crucial for stability, preventing vibrations during use. The fence type and adjustability affect the accuracy of milling. A dust collection system is important for keeping the work area tidy.

Choose a table that fits the size of your workpieces, has a flat top, a warranty and reliable customer support. Cutters soon build up, so think about storage capacity and availability of accessories. Factor in the portability of the table and your budget with your final decision.

1. Size

The size of a router table is directly related to the size of the workpiece it can handle. A large table will provide support for longer and wider boards, so is ideal for bigger projects. When selecting a table size, consider your workshop space, the type of router, and size of your wood pieces.

A 32-by-24-inch freestanding router table is suitable for larger projects. However, it may not be practical for smaller workshops or job sites due to its weight. Benchtop router tables are compact and portable but can only handle smaller workpieces.

Consider the dimensions of the table router, ensuring that it’s comfortable to work with; my workbench is too tall at 38″.

2. Adjustments

There are several things to consider. The first is above-table height adjustment, allowing you to set a router bits projection exactly. Look for a fine adjuster that allows for incremental changes in elevation.

A precision fence system also has sub-fences to open and close the opening around the cutter. They should be adjustable and lock securely in place. Finally, a router lift plate lets you modify the router bit height from above without removing it. This adds versatility and convenience to your routing operations.

3. Weight

Weight is a consideration when buying a router table since it impacts stability. Heavier tables are usually cast iron to reduce vibrations and maintain workpiece control. A heavier table is more stable, while a lighter one is more portable.

The mounting plate should be rigid enough to support the weight of the router and anchor securely in place.

4. Types of design

Various types of router tables are available on the market, each with its pros and cons.

- Benchtop Router Table. This type of router table is designed to be placed on top of a workbench or cabinet. It is usually compact and portable, a great choice if you’re constantly moving stuff around.

- Stand-Alone Router Table. A stand-alone router table is a more robust version of the benchtop model. It has its own legs and can be moved around with casters, but is heavier and less portable.

- Extension Router Table. An extension router table attached to the side or end of a table saw creates an all-in-one workstation. The router extension table is ideal for individuals with limited room who want both in one unit.

- Cabinet-Style Router Table. A cabinet style router table is like a stand-alone model but has additional storage in the base. This freestanding table is great for professional woodworkers with plenty of room.

5. Surface material

The router table top should be at least flat and level to ensure joinery perfection. The most common materials used for surfaces are MDF, phenolic, and aluminum. MDF is durable and stiff but can absorb water and blow (puff up) or deteriorate. Melamine coated MDF, and high-pressure laminate (HPL) provide extra protection and strength.

Phenolic is thinner than MDF, is not damaged by water, and should retain its shape for its lifetime. However, it is more expensive. Aluminium work surfaces are robust but can be heavy.

Smooth surfaces reduce friction and avoid scratches on wood pieces. Picking a material that is durable and ready for the long term is important.

6. T-Slots

T-slots are long grooves that run the length of a router table surface. Router table accessories like adjustable feather boards and hold-downs can be securely mounted. For example, a miter gauge can be attached for angled cuts and greater precision. T-track has a T-shape, with a wider gap providing even more attachment options.

7. Mitre Gauge

In my own personal opinion, a mitre gauge on any of the tables above is just asking for pain and trouble. Yes, it will work with an Incra-style fence, and that’s fine. But to use any of the above fences, each side will need adjustment to keep the mitre gauge slot in parallel alignment; there’s the pain. If you have to move the fence a few times to creep up on an end grain cut, even more trouble.

A better solution is to get a coping sled for running against the infeed fence. Or make your own sled with a sacrificial waste board, it’s easy enough; you can thank me later.

8. Dust Removal

For best performance and your health, consider dust removal when shopping for a router table. Look for built-in dust collection or dust shrouds to capture most of the sawdust.

The perfect deal is dual dust collection ports that extracts from the table underside and above together. A well-designed dust collector prevents clogging and ensures efficient dust and debris containment. Cleaning the dust extractor felt bag regularly maintains efficiency for all router table operations. Don’t forget to always wear a face mask.

9. Power Switches

One of the key features to consider is that the power switch, or NVR switches (No Volt Release), help prevent accidents by inadvertent activation. The best safety switches are easily accessible, with a big red button or paddle.

FAQ

Q: What kind of router should I use with my table?

A: You can use any router with your table; just make sure it’s compatible. Look for variable speed routers with a base that can be easily attached to the table. Also, consider higher horsepower routers with 1/2″ collets as they handle big and more complex jobs.

Q: How do I secure my router to the table?

A: Securing your router to the table is essential for safety and accuracy. Look for tables that have quick clamps or other mechanisms to secure the router in place. Make sure the router is centered on the table and that the bit is properly aligned with the fence.

Q: What is the difference between a router table and a woodworking router?

A: A router table is a stationary tool that holds a router upside down under a flat surface. While a woodworking router is a handheld tool used to cut and shape wood. Router tables have more control, accuracy and the ability to use the biggest diameter profiles. While a wood router is portable and can be used for numerous carpentry tasks.

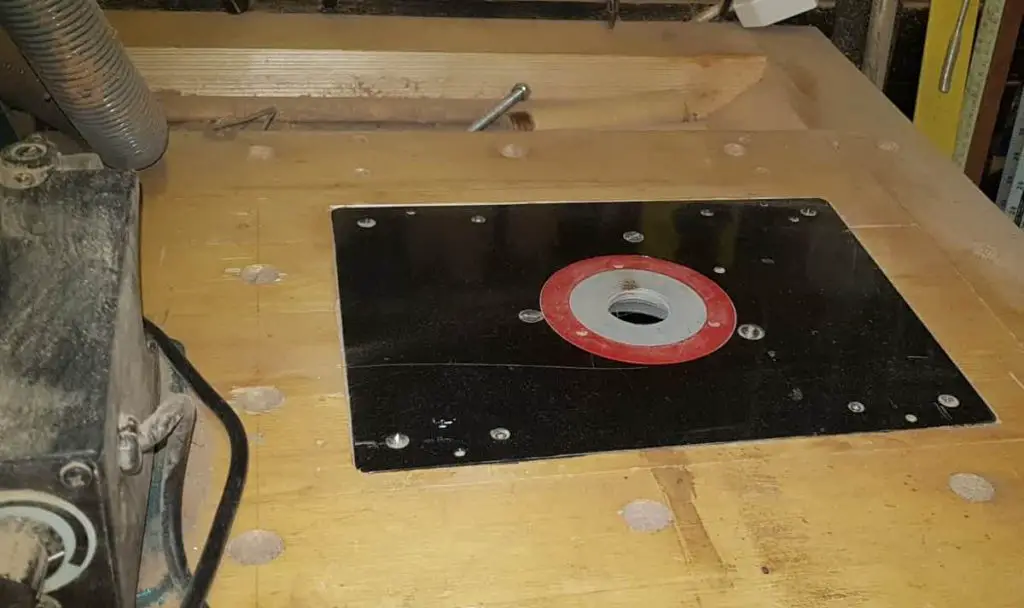

What is the difference between a fence and a router plate?

A router table fence and router plate are two essential components of a router table. The fence is used as a straight edge when running material through the cutter. It can be a single piece or split fence, with the latter being more versatile for jointing edges of boards. A sturdy and easily adjustable fence is critical for precise cutting.

On the other hand, a router insert plate is the mounting or base plate that attaches to the router and fits into a recess in the tabletop. It supports the router weight and must be made of a solid material like aluminum alloy or phenolic resin. The base plate style must also be compatible and aligned with the router hole patterns. A good router table will have a plate-levelling process that consists of four or more levelling screws.

- Router tables come with multiple insert rings to suit different hole diameters.

- The size of the insert ring should closely match the router bits diameter being used.

- The number and size of inserts will determine the versatility, allowing for more choices of bit sizes.

Making the Right Choice

Purchasing the right one for you can be challenging and expensive. Making your own DIY router table with Formica laminate and T-track is a good option for those who want to save money. Formica is a popular material for router tabletops due to its low feeding resistance. It is also easy to clean with good impact resistance. Then stump up for a Triton router with a half-inch collet.

It requires some woodworking skills to make sure the insert plate is perfectly level. If you are not confident in your skill to make your own, consider purchasing a pre-made table or kit.